Laser Cleaning of Anilox Cylinders

ECO Friendly + Efficient

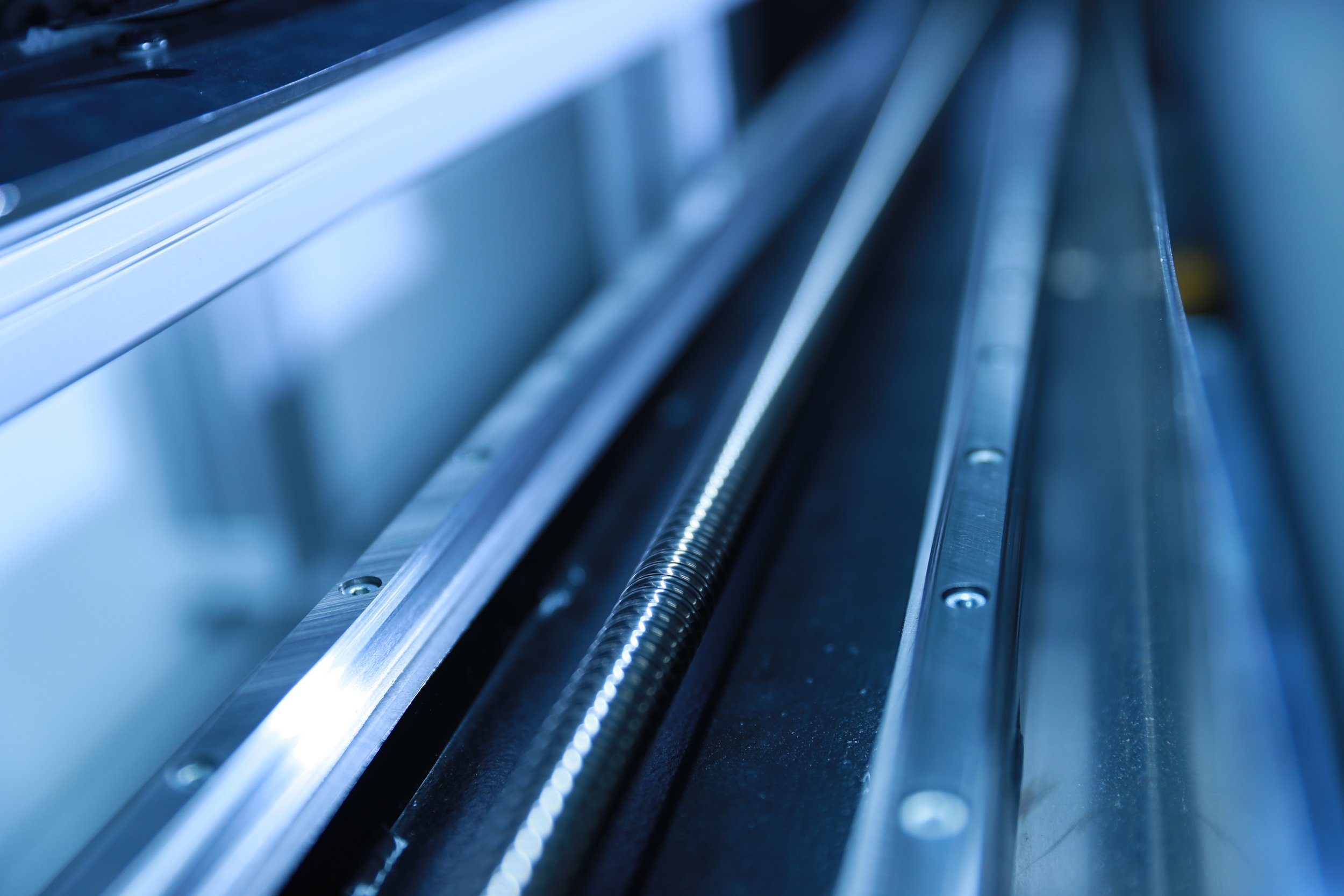

TWEN's laser cleaning technology revitalizes Anilox cylinders in each printing shift, eliminating transfer loss and color variations. This eco-friendly method is waste-free and doesn't require consumables. As a leading provider of laser cleaning solutions for the flexible packaging industry, TWEN Laser Cleaning offers advanced technology and expertise for efficient and eco-conscious contaminant removal and quality enhancement of packaging materials. Maintaining a clean production environment is vital in the flexible packaging industry. Traditional cleaning methods involving chemicals, solvents, or abrasives can be time-consuming, labor-intensive, and lead to residue or damage. TWEN Laser Cleaning addresses these challenges with a non-contact, precise, and non-abrasive cleaning solution. TWEN Laser Cleaning stands out as an environmentally friendly option. Laser cleaning is non-toxic and sustainable, unlike traditional methods that use harsh chemicals and generate waste. It eliminates the need for chemical disposal, reduces water and energy consumption, and promotes eco-conscious practices in the industry.

Sustainable + Fully Automated

TWEN Laser Cleaning offers an advanced and sustainable solution tailored to the flexible packaging industry. With state-of-the-art laser technology, precise cleaning capabilities, and environmental benefits, TWEN empowers manufacturers to achieve higher cleanliness, quality, and efficiency standards. The process is fully automated, requiring minimal operator intervention. It ensures no damage or abrasion to the Anilox surface while being environmentally friendly, generating no waste or pollution. The system is designed to be safe and user-friendly, saving time and enhancing production efficiency compared to other methods. It offers effective and deep cleaning, even in hard-to-reach areas. No consumables such as water or chemicals are required, minimizing risks to your Anilox. Maintenance costs are low, and operating costs are limited to electricity. The system can clean up to 8 Anilox cylinders in each cleaning cycle. Visible reductions of 0.5cc3 x mm2 can be observed, ensuring optimal performance for densitometers.